2G Biogas Treatment Solutions

Biogas can be a very harmful fuel source with many highly reactive chemicals capable of doing major damage to an engine.

All 2G Biogas plant systems are available with a full range of biogas cleaning equipment to ensure your valuable CHP investment is protected.

2G’s complete biogas cleaning and filtration systems are specifically designed and engineered to suit our biogas CHP systems. Don't risk major engine damage with untreated biogas.

Our biogas treatment solutions comprise of three solutions;

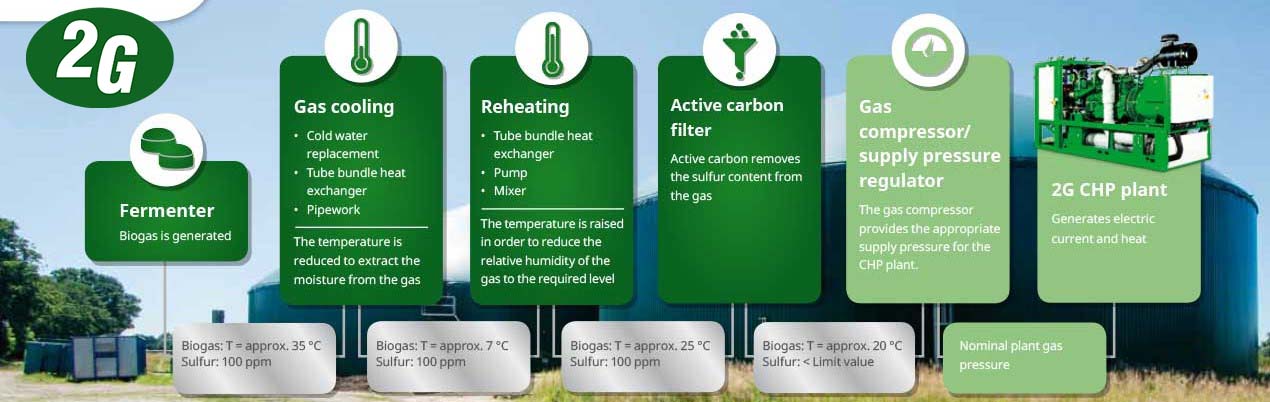

Biogas Dehumidification and Reheating

Biogas usually has a very high water vapour content. During periods of cold weather this water vapour can condense inside the gas pipework and react with chemicals such as H2S, NH3, CO and H2 to create highly corrosive compounds.

Additionally the high water content reduces the performance of the CHP system. Removing water vapour via dehumidification significantly improves the performance and reliability of a cogeneration unit.

Contact Evo Energy Technologies for further information on our biogas dehumidiciation and reheating solutions.

Gas Cooling

The temperature is reduced to extract the moisture from the gas.

- cold water replacement

- tube bundle heat exchanger

- pipework

Contact Evo Energy Technologies for further information on our gas cooling solutions.

Activated Carbon Filtration

High concentrations of Sulphur and Siloxanes in biogas can cause corrosion, wear, oil contamination and silicone deposits on internal combustion components leading to very high service and maintenance costs and reduced engine efficiency. Activated carbon filtration removes high amounts of these damaging impurities.

Alternatively, a gas wash dryer can be combined with an active carbon filter. The gas wash dryer cools the biogas down to 2-4°C and cleans the biogas more thoroughly, which is advantageous for micro gas networks.

Contact Evo Energy Technologies for further information on our activated carbon filtration solutions.

Contact us for further information about 2G gas drying, cooling and activated carbon scrubbing equipment specifically designed to match a 2G system.