BettaPork is one of Australia’s leading sustainable pork producers who specialise in delivering high quality, environmentally friendly pork products.

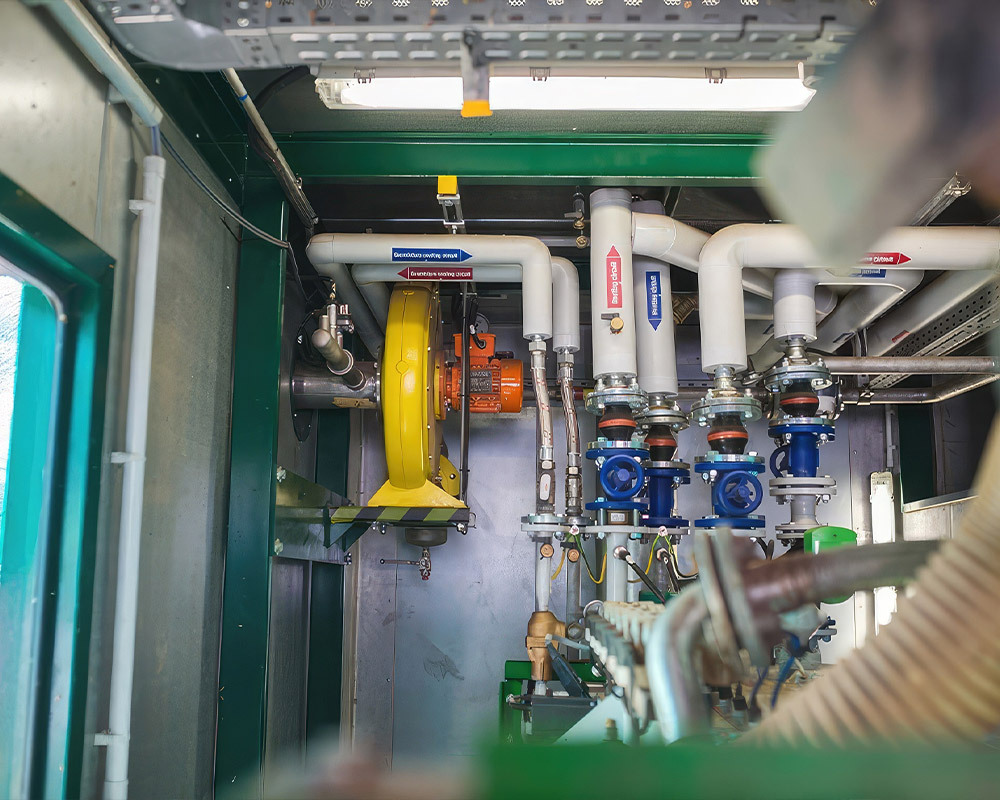

In 2015, Evo Energy Technologies supplied BettaPork with two 2G Filius 106 100kW biogas engines in a Twinpack container module and again in 2019, another 2G Agenitor 408 360kW biogas engine that converts BettaPork’s organic waste into energy

Evo ET’s advanced technologies save BettaPork hundreds of thousands of dollars on their energy costs every year whilst benefitting the environment.

Creates enough electricity to power 140 homes

Saves Betta Pork hundreds of thousands of dollars on their energy costs every year

Sustainable waste-to-energy solution

EvoET’s 2G Filius & 2G Agenitor CHP solution for BettaPork sees the conversion of 120,000 litres of organic waste every day expelled as around 200kW worth of power – enough to power the entire farm for majority of a day, as well as the Brosnan family’s housing.

The waste in the tanks is eaten by organisms that eat the organic material, then excrete the gases as methane. The methane floats to the top of the tank where it is then pushed through stainless steel pipes under extremely low pressure to a generator through a carbon filter to remove hydrogen sulphide. Finally, the methane enters the CHP engines which are designed to run on gas instead of fuel.

By partnering with local schools, abattoirs and restaurants, more organic waste is that would otherwise go to landfill is utilised to generate more clean energy.

Additionally, the roughly 100kW of excess power that is generated is used to Australian Piggery which generates additional income.

BettaPork is an industry leading example of sustainable farming, and have set an excellent benchmark for the industry to aim for.